Gold’s Role in AI Hardware: Why It’s Essential for 2026 Processors isn’t about jewelry—it’s about keeping trillion‑dollar compute from failing because of a microscopic, boring, physical problem: bad connections.

AI is a “software” story on the surface. But under the hood, it’s a hardware stress test. 2026 processors (GPUs, TPUs, NPUs, custom ASICs) will push power density, bandwidth, and packaging complexity so hard that the weak link is no longer the code. It’s the metal touching metal.

And this is where gold quietly wins.

Not because it’s trendy. Not because it’s rare. Because when the stakes are high, gold is the cheapest insurance policy you can buy.

This article is educational. It’s not financial advice, investment advice, or engineering certification guidance. Specs, amounts, and costs vary by design and vendor. Use this as a framework, then verify with primary sources for any decision.

Why this matters in 2026 (the “multi‑million dollar millisecond”)

When a consumer laptop glitches, you restart.

When an AI training run glitches, you can lose:

- Days or weeks of compute time

- GPU cluster availability

- Engineering hours and deadlines

- Customer SLAs and revenue

One flaky contact can throw errors, degrade signal integrity, or cause hard failures—especially under heat, vibration, and constant current.

The uncomfortable truth: the bigger the AI model, the less tolerance you have for tiny physical failures.

This is the core thesis:

In 2026 AI hardware, the value of reliability is bigger than the cost of materials.

If you want the “big picture” version of gold powering modern tech, start here: Gold and Technology: The Precious Metal Powering Our Future.

Buy Gold Online: The Smart and Secure Way

Discover the safest and most reliable strategies to buy gold online. Make informed investment decisions and secure your financial future today!

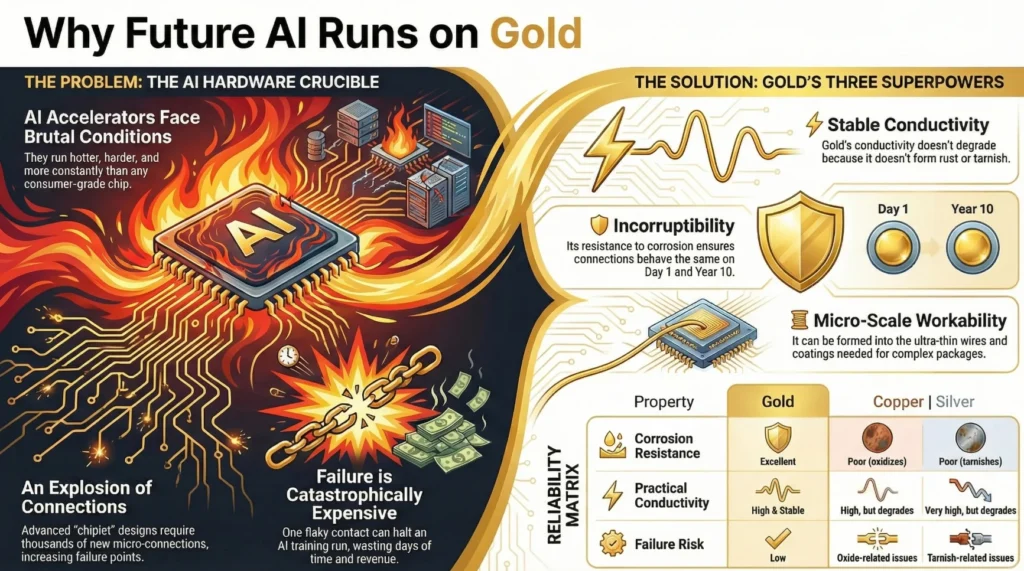

Learn MoreThe unchanging standard: gold’s three “superpowers” in electronics

Gold has dominated high‑reliability electronics for decades. Not because it’s the best at one thing. Because it’s excellent at the three things that matter most at scale:

1) Conductivity that stays predictable

Gold isn’t the #1 conductor (silver and copper beat it). But gold’s conductivity is stable and repeatable in real‑world conditions—because it doesn’t form nasty surface layers the way many metals do.

In plain English: it keeps signals clean.

2) Incorruptibility (the killer feature)

Gold does not rust. It does not oxidize like copper. It does not tarnish like silver. That “boring” property is priceless when you need a connection to behave the same way:

- Day 1

- Year 5

- Year 10

- Under heat cycles, humidity, and contamination

3) Workability at microscopic scale

Gold is insanely ductile and malleable. That means you can:

- draw it into ultra‑thin bonding wire

- plate it in extremely thin layers

- create reliable contact surfaces without cracking

This matters because modern packages are basically a city of micro‑connections.

Quick visual summary: Gold’s three pillars

- ⚡ Conductivity (low resistance, stable signal paths)

- 🛡️ Corrosion resistance (no oxidation, long‑term integrity)

- 🧵 Malleability (works in tiny wires and thin coatings)

Table 1: Why gold keeps getting chosen (even when it’s expensive)

| Property that matters in AI hardware | Gold | Copper | Silver | Palladium / other plats |

|---|---|---|---|---|

| Conductivity (practical) | High and stable | High, but oxidizes | Very high, but tarnishes | Lower (varies) |

| Corrosion / tarnish resistance | Excellent | Poor without protection | Poor in sulfur environments | Excellent |

| Micro‑scale manufacturability | Excellent | Good but harder | Moderate | Good but costly |

| Common use in connectors / plating | Very common (thin plating) | Underlayer + plating | Sometimes (special cases) | Niche |

| Typical failure risk | Low | Oxide‑related contact issues | Tarnish‑related resistance | Process/cost complexity |

If you want the “electronics basics” version (connectors, contacts, boards), here’s a deep dive: How much gold are in computers?

The AI crucible: where standard components fail and gold excels

Think of a consumer CPU like a commuter car.

An AI accelerator is closer to a Formula 1 engine:

- extreme power

- extreme thermal stress

- extreme bandwidth

- constant duty cycle

AI hardware has three brutal requirements

1) Extreme power density

AI GPUs and accelerators run hot, hard, and often near their limits. High current plus high temperature is where connection problems get amplified.

Heat does two nasty things:

- It expands and contracts materials (thermal cycling)

- It speeds up degradation mechanisms (like diffusion and interface fatigue)

Gold helps because its surfaces stay clean and its contact behavior stays consistent.

2) Massive data throughput (the data firehose)

Modern AI is limited by memory and interconnects as much as compute. The processor must move huge amounts of data to and from HBM (High Bandwidth Memory).

That means:

- thousands of connections

- very dense routing

- high signal integrity requirements

The more connections you have, the more “lottery tickets” you buy for failure. Gold reduces the odds.

3) The price of an error

A tiny connection issue can cause:

- bit errors

- intermittent faults

- performance throttling

- complete node failure

In a consumer machine, that’s annoying.

In AI infrastructure, it’s expensive.

Table 2: CPU vs AI accelerator (why the interconnect problem explodes)

| Metric | Consumer CPU | Data center AI accelerator (2026‑style trend) |

|---|---|---|

| Typical workload | Burst + idle | Sustained, near‑constant |

| Power draw | Low to moderate | Very high |

| Memory architecture | DDR/LPDDR | HBM stacks + complex I/O |

| Connection density | Moderate | Extreme (package + board) |

| Tolerance for errors | Some | Very low |

| Cost of downtime | Low | Very high |

✅ “Cost of Failure Reality Check”

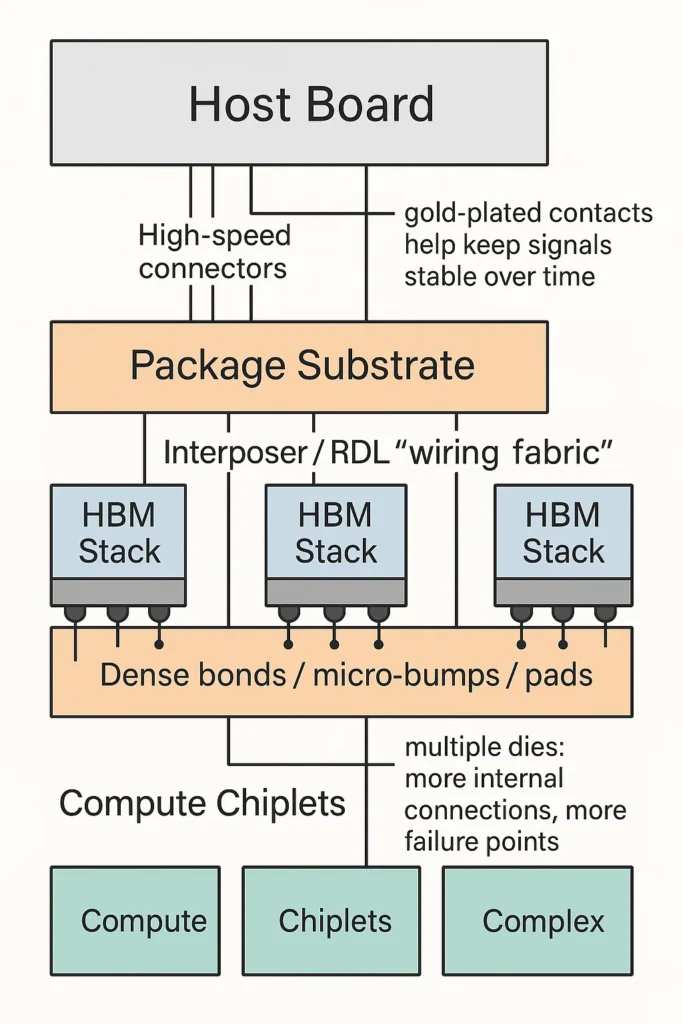

The 2026 blueprint: why advanced packaging makes gold more critical than ever

Here’s the part most articles skip.

They talk about “gold in electronics” in general, then stop.

But 2026 processors aren’t just smaller transistors. They’re more complex physical systems. The game is shifting from “make the die smaller” to:

- split the die into chiplets

- stack memory next to compute

- cram interconnects into 2.5D/3D packages

- push signals through insane bandwidth at short distances

From monoliths to chiplets: the interconnect explosion

As chips get more complex, building one giant monolithic die gets harder:

- lower yields

- higher cost

- more heat concentration

- more design risk

So the industry moves to chiplets (multiple smaller dies) stitched together in one package.

This creates an obvious consequence:

More dies = more die‑to‑die connections.

And those connections must survive:

- heat

- vibration

- time

- contamination

- mechanical stress

Examples that show the direction (already here today):

- multi‑tile accelerators

- CPU + GPU “superchips”

- stacked cache, stacked memory, stacked everything

HBM isn’t optional anymore

HBM (High Bandwidth Memory) is the fuel line of modern AI. 2026 accelerators will keep pushing:

- higher bandwidth

- more stacks

- tighter placement near compute

So you get:

- more interposer routing

- more micro‑bumps / pads

- more connectors that must stay perfect

Anatomy of a “2026‑style” AI processor (simplified)

If you want the broader “AI + future computing” angle, this page connects the dots well: How gold is used in AI and quantum computing

The “how”: where the gold actually goes inside AI hardware

Let’s kill a common misconception:

Gold isn’t used because engineers are “lazy.”

Gold is used because the physics of contact and corrosion are brutal at micro‑scale.

Here are the main places gold shows up in AI hardware:

1) Wire bonding (the microscopic stitching)

Wire bonding is a method that connects a die to its package with extremely thin wire.

A bonding machine makes thousands of tiny connections, fast.

Gold has been a classic wire‑bond material because it is:

- easy to form

- consistent in bonding behavior

- stable against corrosion

Yes, copper wire bonding is common too. But for high‑reliability and certain process windows, gold still stays in the conversation.

For a packaging‑industry perspective on why this method remains widely used, see: Wirebonding is here to stay

2) Gold plating on contacts (connectors and pads)

Gold is often used as a thin plating layer on:

- connector pins

- contact pads

- high‑reliability board interfaces

Because the goal is not “bulk gold.”

The goal is: a surface that doesn’t turn into garbage over time.

3) Gold bumps, studs, and micro‑contacts

In advanced packaging, you also see gold used in:

- stud bumping

- specialized interconnect features

- ultra‑small contact points that need predictable behavior

Table 3: Where gold lives in an AI accelerator (and what it prevents)

| Component | How gold is used | Why it’s used | What goes wrong without it |

|---|---|---|---|

| Connectors (board, risers) | thin gold plating | stable contact resistance | oxidation → intermittent failures |

| Package bonding | bonding wire / micro contacts | consistent micro‑bonds | weak joints, fatigue, voids |

| Pads & finishes | gold surface layer | corrosion protection | surface films → signal loss |

| High‑speed interfaces | gold-plated contacts | clean high‑freq behavior | noise, jitter, dropouts |

| Long-life systems | thin protective layers | years of reliability | degradation over time |

Want an even more general baseline? This explainer is a good internal reference: Gold in 5G and future telecommunications

The economic equation: quantifying AI’s hunger for gold (without hype)

Let’s be careful here.

No one outside manufacturers can quote exact gold content per AI processor because:

- designs differ

- suppliers differ

- finishes differ

- packaging differs

So don’t treat any single number like gospel.

But you can reason about the scale.

A simple way to think about it

Gold use in advanced electronics is usually:

- thin (plating measured in micro‑layers)

- targeted (only where contact reliability matters)

- high leverage (tiny mass, big reliability impact)

Industry discussions often talk about tens of milligrams of gold in high‑end packages (sometimes higher, sometimes lower). The point isn’t the exact number.

The point is what happens when you multiply it.

Multiply the micro by the macro

If an industry ships millions of high‑end accelerators, even small amounts become meaningful at the “tonnes” level.

And the World Gold Council’s reporting shows technology demand is a real slice of annual gold demand (not the biggest slice, but not trivial either). For context, see the World Gold Council’s section on technology demand trends: Gold Demand Trends – Technology

✅ “AI Gold Demand Estimator”

No scripts. Just a clean estimator framework you can calculate in 30 seconds.

Supply chain reality: where the gold comes from (and why recycled gold matters)

AI doesn’t just need chips. It needs:

- stable inputs

- predictable supply

- consistent quality

Gold has a big advantage: it has a mature global supply chain.

But there’s a unique “2026” opportunity that’s underused in most discussions:

Recycled gold from e‑waste

Electronics contain gold. Not a lot per device. But enough that recycling becomes meaningful when scaled.

Recycled gold can be:

- high purity

- lower environmental footprint (depending on process)

- a strategic supplement when demand spikes

If you want the recycling angle, this is a must‑read: How gold is extracted from e-waste

Geopolitics: gold vs “rare earth panic”

A lot of critical tech inputs are concentrated in a few regions.

Gold is produced and refined globally. That doesn’t eliminate risk—but it reduces single‑point dependency compared to some niche minerals.

For a high‑level US reference on gold’s industrial importance, see: USGS Gold statistics and information

The contenders: why alternatives still fall short

If gold is so great, why isn’t everything gold?

Simple: cost.

So engineers constantly try alternatives. The problem is: alternatives usually fail on the exact axis AI cares about—long‑term reliability.

Silver: the tarnishing runner‑up

Silver conducts extremely well.

But it tarnishes (sulfidation), which changes surface behavior and contact resistance over time. That’s a deal‑breaker in many high‑reliability interfaces.

Copper: the workhorse with a flaw

Copper is cheap and conductive.

But copper oxidizes easily and can suffer from reliability issues at micro‑scale and high density unless it’s protected, coated, or engineered very carefully.

Copper wins in many places. Gold wins where failure is unacceptable.

“Advanced” coated materials: promising, but risky

You’ll hear about:

- coated copper

- exotic alloys

- graphene‑adjacent ideas

Some will work in specific niches.

But for mission‑critical AI hardware, manufacturers move slow. Because reliability testing takes time—and failures are expensive.

Beyond 2026: why gold’s role doesn’t end with GPUs

If you want to outrank the typical “gold is used in electronics” article, this is the section that separates you.

Optical I/O and silicon photonics

As electrical signaling hits limits, the industry pushes toward more optical interconnects.

Gold’s stability and optical properties can matter in photonics modules (coatings, contacts, precision surfaces).

Neuromorphic and quantum computing

Quantum and neuromorphic systems have extreme sensitivity requirements. Gold’s stable conductivity and compatibility with certain fabrication steps keeps it in the toolbox.

This is why gold isn’t “going away.” It just moves to where the performance frontier is.

The takeaways (read this if you skimmed)

- Gold is used in AI hardware because it stays reliable when other metals degrade.

- AI accelerators push power, heat, and bandwidth so hard that connection failures get expensive fast.

- 2026 packaging trends (chiplets, HBM, 2.5D/3D) create an interconnect explosion. More connections means more risk.

- Gold is often a thin layer in the right place, not a big chunk. Tiny mass, huge impact.

- Recycled gold from e‑waste is an underrated supply‑chain lever.

FAQ: Gold and 2026 AI processors (5 fast answers)

Tip: These are framed to match real “People Also Ask” queries and reduce confusion.

1) How much gold is actually in an AI processor?

Usually not a lot by weight. Gold is often used as thin plating or micro‑connections. The important point is reliability, not bulk content.

2) Will gold be replaced by copper or silver?

In some applications, yes. In mission‑critical contacts and certain micro‑scale connections, gold remains hard to beat because it doesn’t oxidize or tarnish.

3) What happens if the price of gold doubles?

For high‑end processors, the gold mass is typically small compared to total product cost. Even a big move in gold price often changes total BOM cost only slightly.

4) Is recycled gold “good enough” for advanced chips?

Yes—recycled gold can reach very high purity when refined properly. The key is process control and certification, not whether the gold came from a mine or scrap.

5) Does AI growth meaningfully increase gold demand?

It can, because AI hardware is shipped at scale and uses dense, high‑reliability interconnects. Even small per‑unit amounts add up when millions of units ship.